Despite its reputation for world-renown opera, Verona has been a challenge to appreciate. The stifling heat, throngs of tourists, and mediocre food, has kept us from wanting to stay longer.

On our day of our arrival, we bought last-minute tickets for the Barber of Seville. For 20 Euros we were seated near the top of the arena on marble steps. We didn’t think much of the inconvenience as we had done the same for the Pop Italian Night in Plovdiv the week before.

However, we underestimated the heat and the crowds. We wiggled our tusches and toes every thirty seconds in an attempt to tolerate the uncomfortable seating. The translation was impossible read, so we numbed our way through the long Italian dialogs, fanned our sweaty faces with printed ticket vouchers, and scusied our bumping elbows with courteous neighbors frequently.

We couldn’t help but wish we were still in Plovdiv, in the mild warm breezes and mellow crowd. Even with limited or no English, the Ancient Theater in Plovdiv just seemed like a more natural and welcoming environment for us to relax and enjoy the music.

The sound was definitely better in Plovdiv., where singers’ voices were amplified. That could be considered sacriligious in the professional opera world, but In Verona, voices sank into the warm air like goop slithering down your hands and forearms. Perhaps weaker performers in Verona simply couldn’t project their voices across a stadium that holds 20,000 spectators (30,000 in its hey-day in 30AD, the peak of Roman civilization)

The second night was quite a spectacular display of Star Wars-inspired stage sets, lighting and costumes synchronized to Verde’s Aida music. Nothing changed from the previous night’s heat or poor acoustics, but the visual effects at least kept us awake. We only got through by dreaming about ice cream after the performance.

Well, you get the drift. I was probably filming everything to avoid bordem. Needless to say, not one of my favorite operas or venues.

Night life in Verona was booming, partly because it was nearly impossible to make use of daylight in the scorching 100 degree weather. It did bring back vague memories of the unbearable heat we experienced with the kids when we visited Italy in 1996.

It was so hot we drove two hours back from Naples in an unairconditioned car, after driving there and realizing how pointless it was to be outside in such extreme weather. It was probably only 85 degrees then and ten degrees less than the weather we faced in Verona, thanks to global warming.

Nevertheless, as mentioned in the previous post, it was the journey, not the destination.

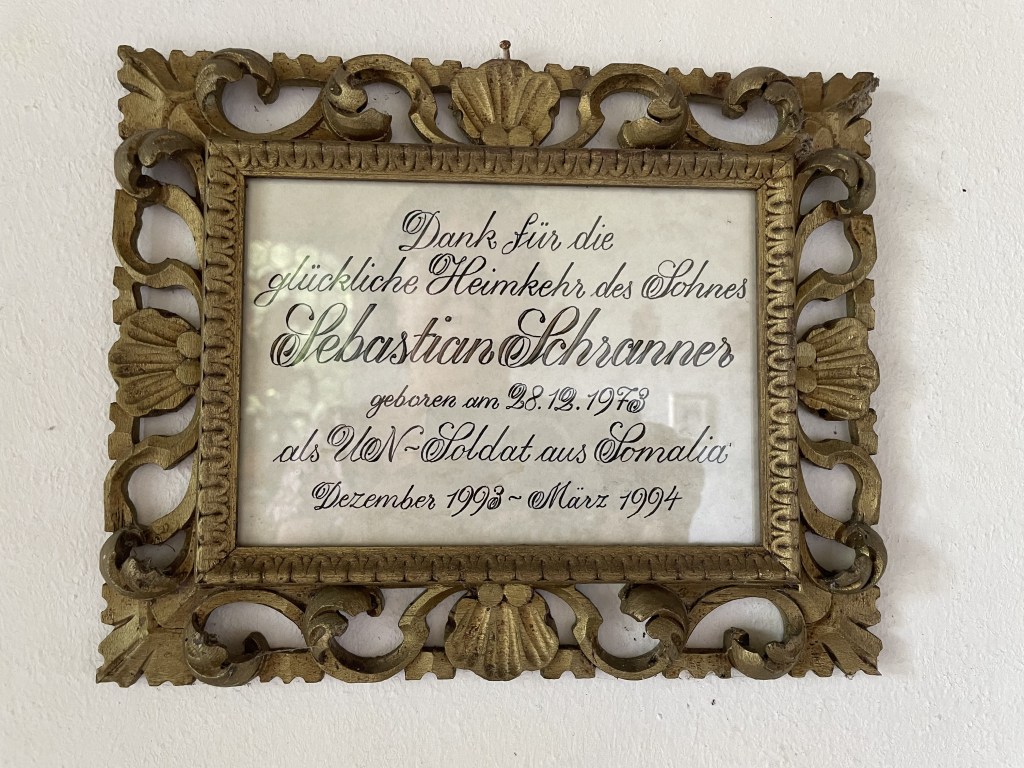

Ettal Kloster

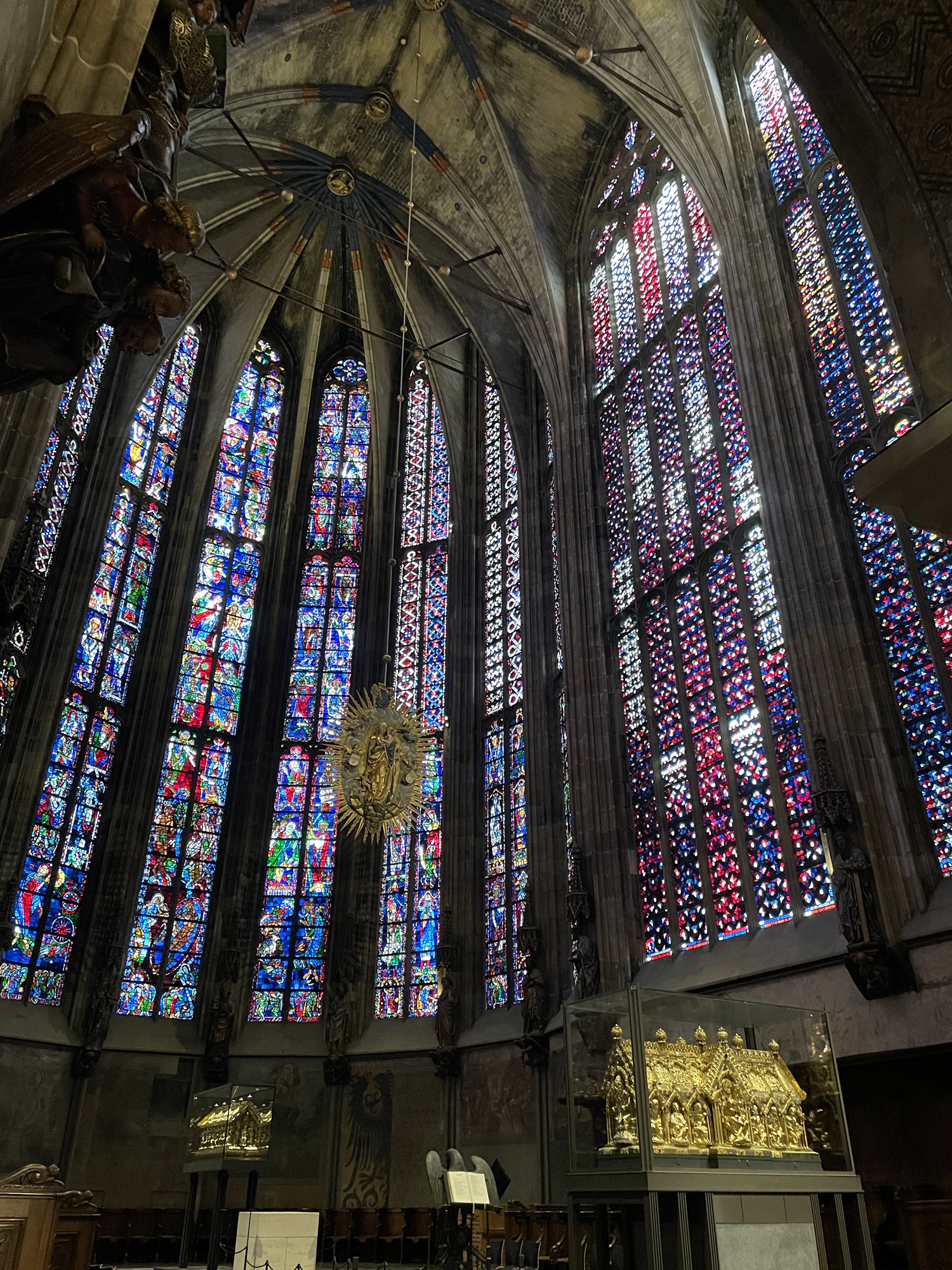

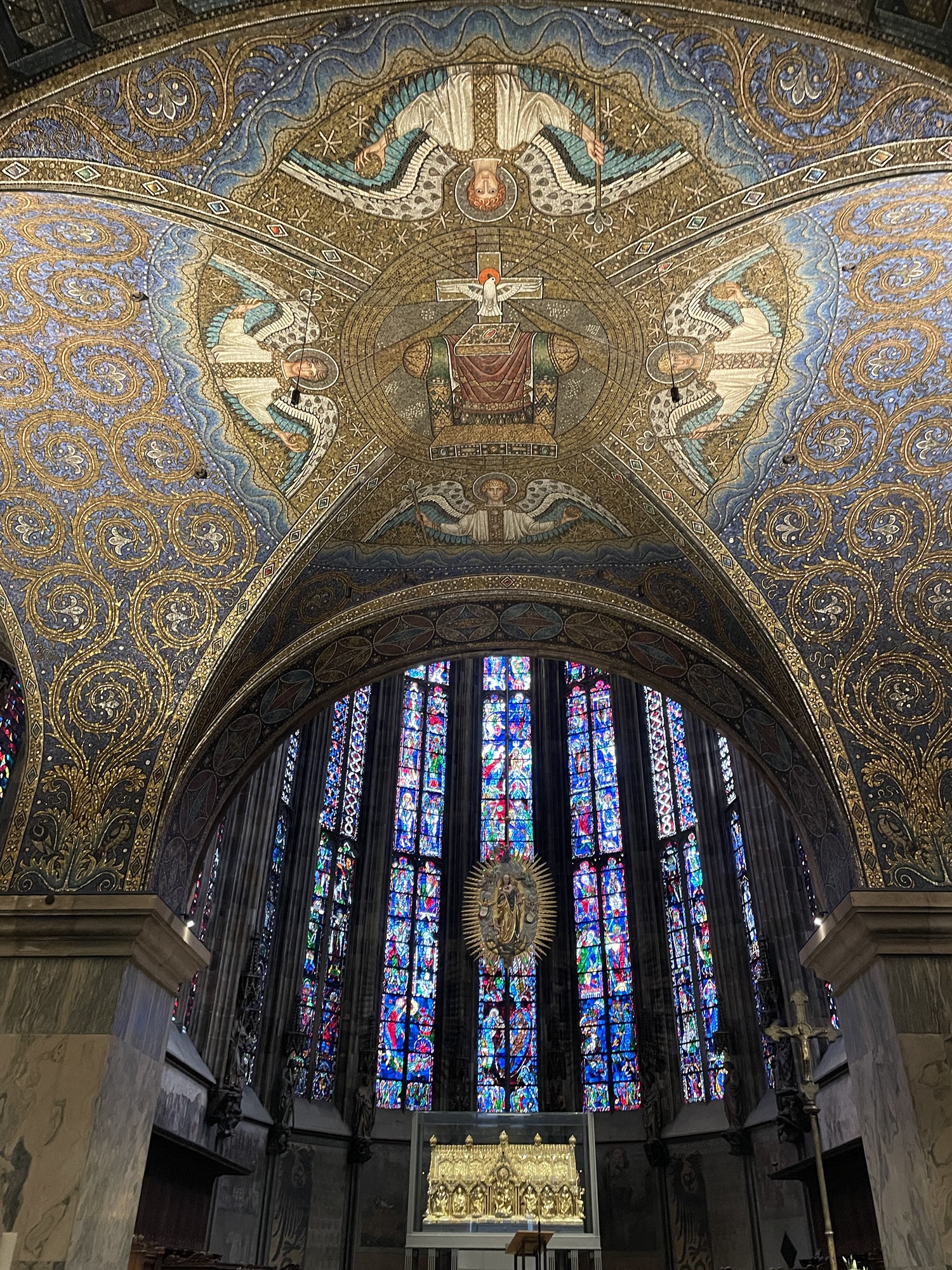

On our way back to Munich and our overnight accommodations in Bad Kohlgrub, we stopped by to see the interior of the Ettal Kloster. I could tell from the exterior of the dome that it was going to be impressive. and indeed, its ornate interior did not disappoint. Having been established in around 1333, the church utilized the masterful painting of the heavens to captivate its parishioners.

Now, I am realizing that this blissful journey has come to an end. Annemarie was the big hit for the day. She took care of me, helped me remember the countless items I left behind, and had my back throughout the entire trip. I met many of her friends and family and really felt for the first time that I was more than a tourist.

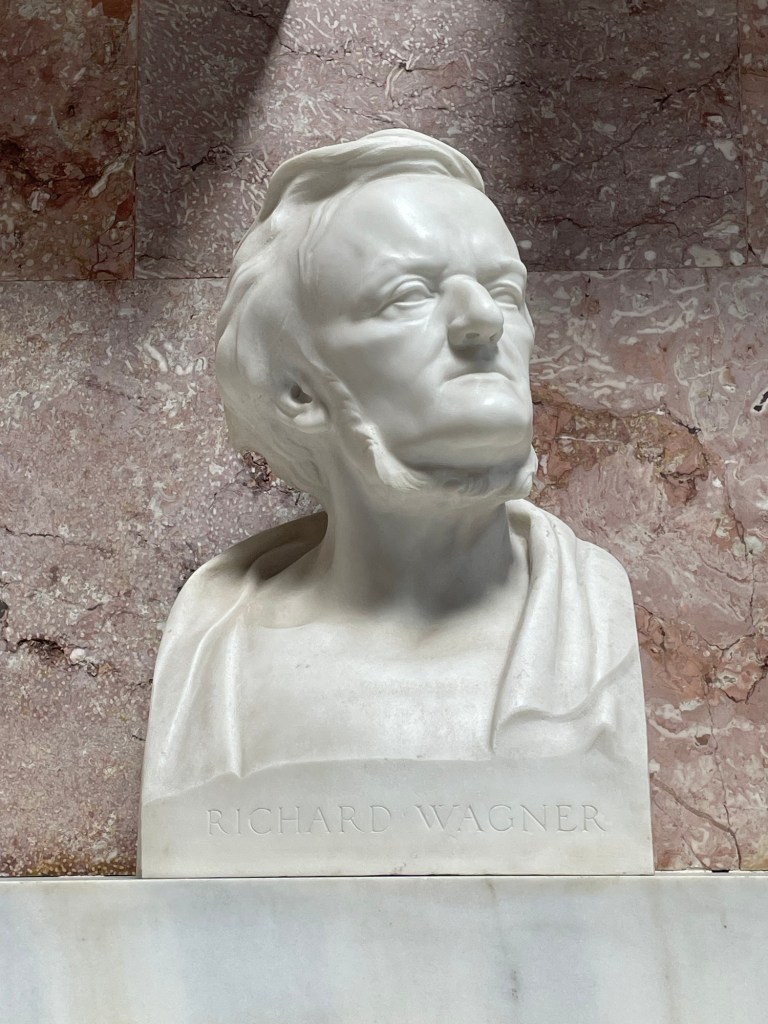

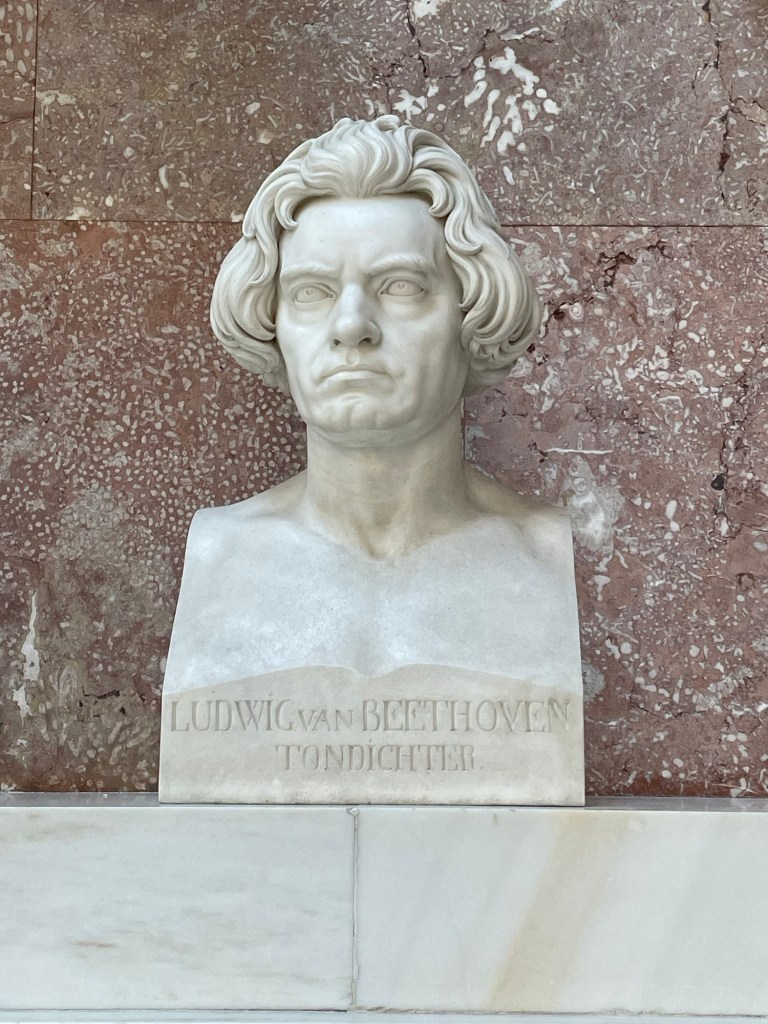

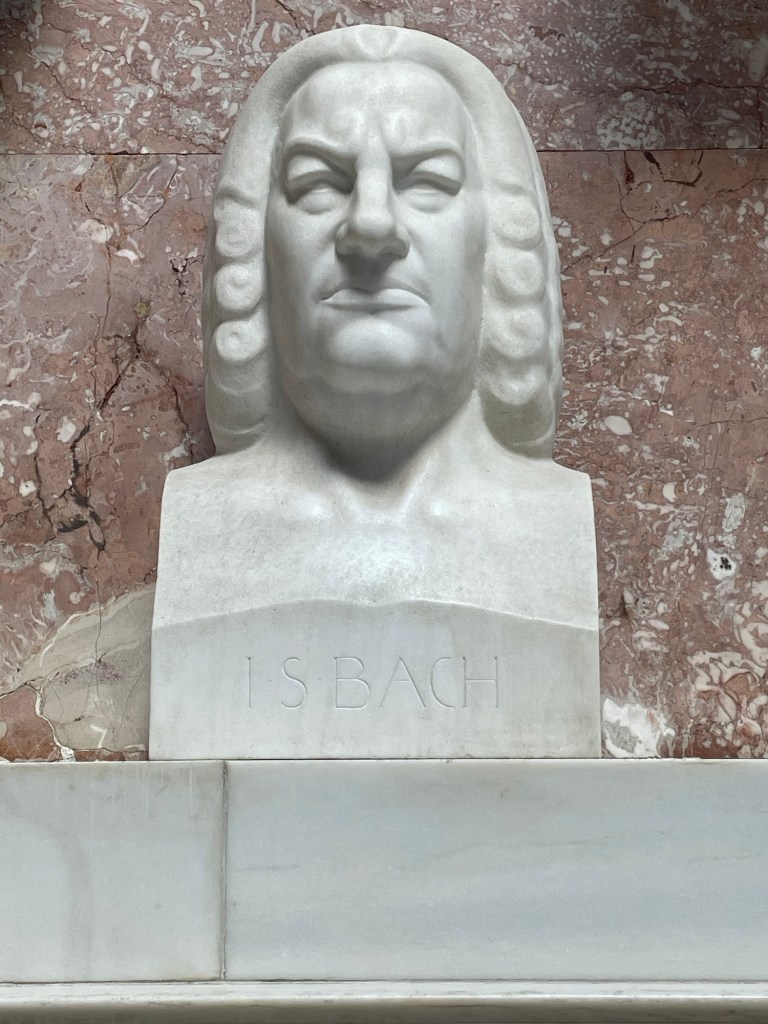

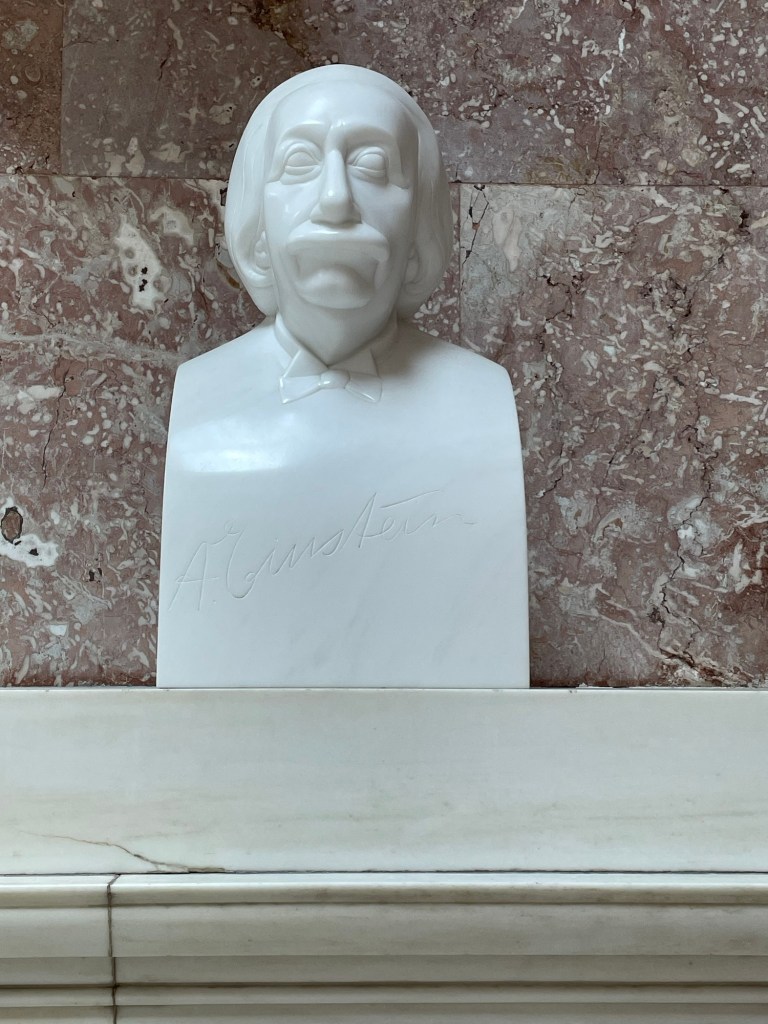

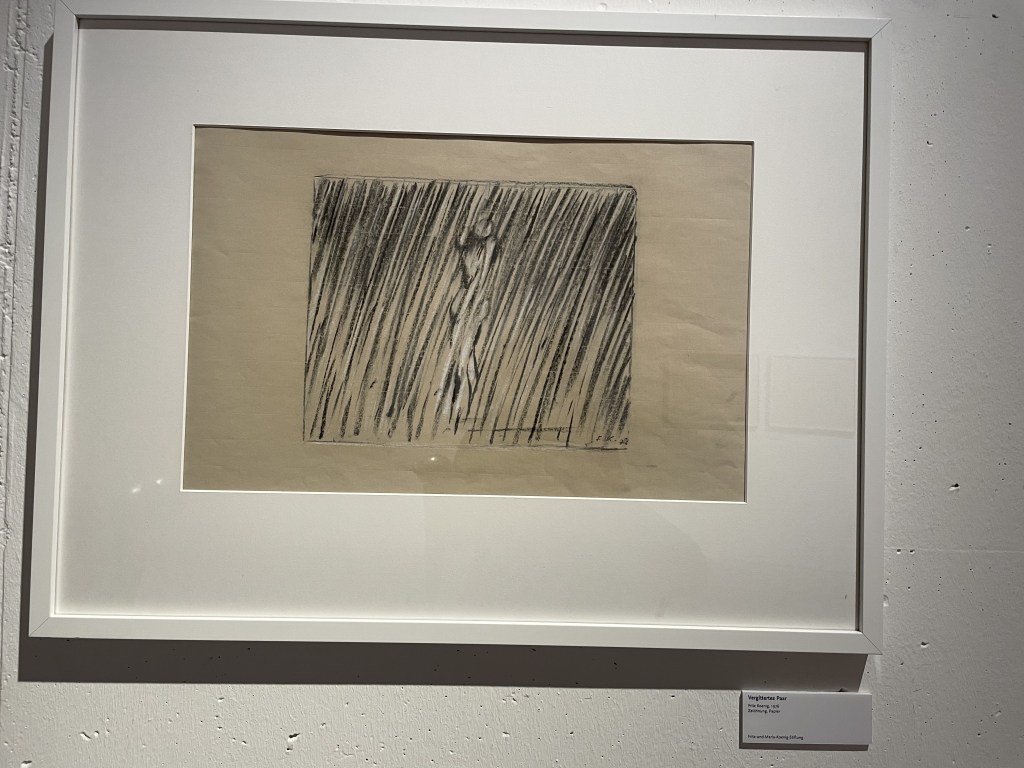

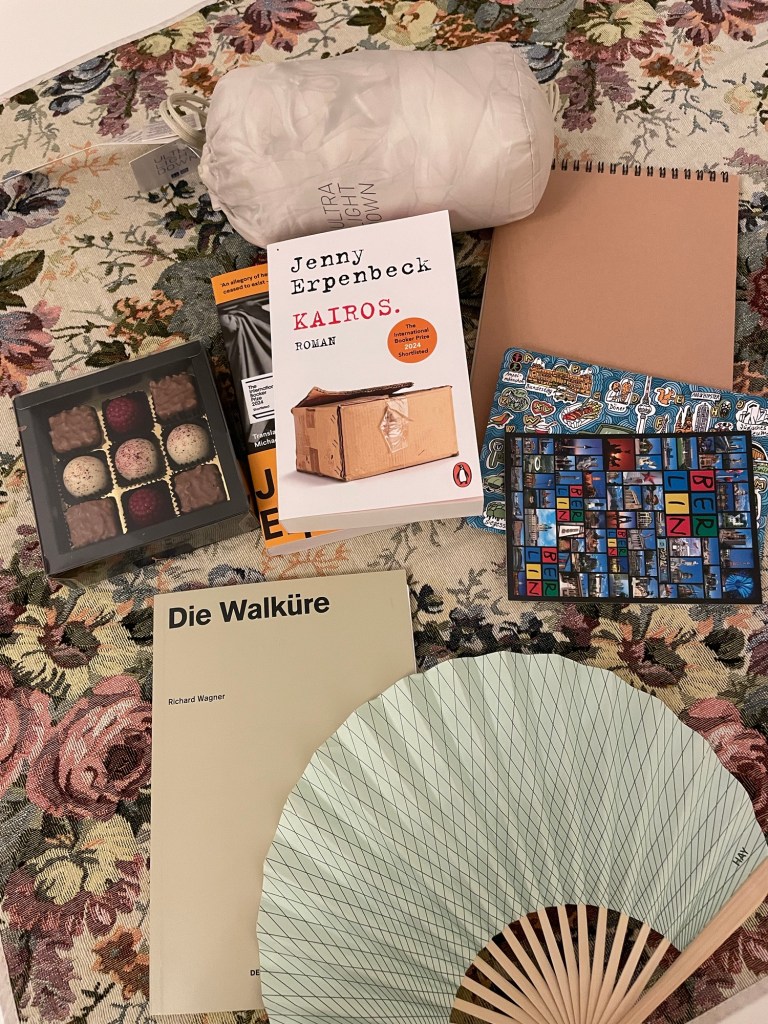

Learning the German language was my entree to a country steeped in history and culture. And the more I travel there, the more it helps me to understand Germany and the world. Its brilliant thinkers, artists, musicians and scientists form a legacy to be continued. Its tainted history is difficult to overcome, but the German people today are attempting to face it.

Thank you Annemarie, friends and family, for all your kindness and gentleness. I will cherish this trip forever. Thank you for sharing your life and world with me.